Gas Operation

Automatic or self-loading firearms operate by harnessing the gas pressure generated upon firing a cartridge to propel the projectile out of the barrel. This energy is redirected to facilitate the automatic ejection of spent casings, loading of fresh cartridges, and resetting of the action for subsequent shots. Termed gas operation, this principle features various methods and subvariations, each functioning on the basis of gas pressure but mechanically differing. Notably, the initial loading requires manual intervention, typically by inserting a magazine or cartridges. An automatic sequence ensues only post-discharge.

This method, employed in automatic rifles, semiautomatic rifles, carbines and for unlocking 20mm automatic guns, consists of diversion of a minor quantity of propellant gas from the bore of the tube into a suitable small cylinder, where it drives a piston connected to ^ie breech mechanism to accomplish the desired operation. In the rifle and carbine this action unlocks the bolt and drives it rearward to withdraw and eject the fired case and compress a spring which returns the bolt to closed position. After the bolt reaches its rearmost position, the next cartridge is pushed into a position ahead of the bolt. The bolt, when it moves forward, drives the cartridge into the chamber and rotates itself by cam action to lock the closure. The weapon is then ready to fire.

ARMY MATERIEL COMMAND ALEXANDRIA VA. (1964)

Gas Impingement

Gas impingement, also known as direct gas operation, involves channeling gas pressure back to the receiver from the muzzle, thus automating the firearm’s action. Gas returns through a tube or channel, directly impacting the action. The renowned AR-15 exemplifies this system, albeit criticized since its adoption by the U.S. military. Interestingly, Eugene Stoner originally developed the AR-10 with a gas piston-driven system, but gas impingement prevailed historically.

According to Walker (2012): “A firearm that operates on gas impingement, which is also called direct gas operation, uses gas pressure returned to the receiver from the muzzle that automatically cycles the firearm’s action. The gas pressure returns to the receiver through a gas tube or channel, where such gas pressure strikes, collides, or impinges directly on the firearm action. The Swedish Ljungmann AG42, introduced in 1942, was such a self-loading rifle that used a gas impingement system, and it became the inspiration for a series of early gas-operated rifles used around the world.”

Gas-Piston Operation

Gas-piston operation presents an alternative to direct gas action, where gas pressure acts upon a piston, which in turn drives the action. Examples include John Garand’s M1 rifle and the German G.43, each employing distinct piston-driven mechanisms.

Gas-piston operation represents an alternative to the direct gas action and may be referred to as an indirect gas-action system because the gas pressure does not directly work with the firearm action; instead, the piston acts as the intermediary between the two. A gas-pistonoperated firearm uses the gas pressure generated by the expanding volume of gas in the fired cartridge to move a piston. The stroke of the piston may be long, or short, relatively

Walker (2012)

speaking. As is the case with all types of firearm actions, there is no singular method by which the gas piston system is employed; there are numerous variations of how the gaspiston action is set up

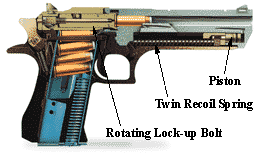

Gas-Operated Semiautomatic Pistols

Although uncommon, gas-operated semiautomatic pistols exist, such as the Desert Eagle, characterized by a fixed-barrel design and gas-driven piston.

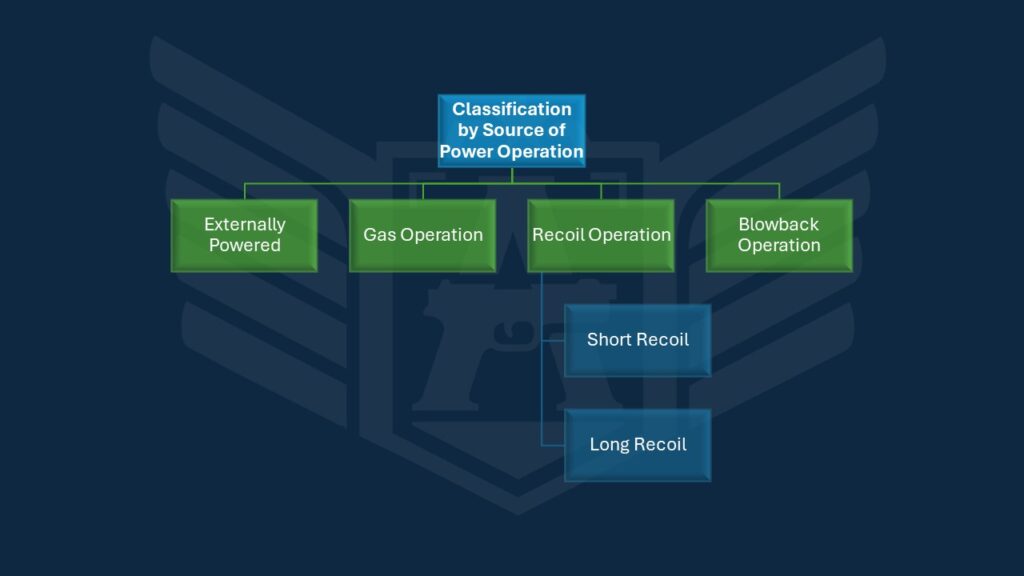

Recoil Operation

Nearly universal among semiautomatic handguns, recoil operation simplifies firearms by utilizing recoil spring(s) to manage rearward motion of the slide upon firing, subsequently ejecting spent casings and reloading fresh cartridges.

Short Recoil

Widely utilized in Army machine guns and semiautomatic pistols, the short recoil system involves the barrel recoiling a short distance into the receiver upon firing. Initially, the bolt remains locked to the barrel, but later unlocks as the recoil continues. During this process, the bolt extracts the fired cartridge case, withdraws a new cartridge, cocks the firing mechanism, and compresses the driving spring. As the bolt moves forward, it advances the feed belt, ejects the fired case, chambers a new cartridge, and returns to the firing position. The recoiling unit, including the breech ring and mechanism, slides in the mount with the assistance of a recoil mechanism, which dissipates and stores recoil energy. A camming device engages the breech mechanism during counterrecoil, opening the breechblock and preparing it for the next round.

Long Recoil

In the long recoil system, the barrel and breechblock or bolt recoil together for the entire distance. The bolt remains held open in the recoiled position as the barrel moves forward to extract the spent case and reload. However, due to its slow rate of fire and limited military application, this system is not commonly used in present military designs.

Blowback Operation

The simplest method for automatic firearms, blowback operation relies on the pressure generated in the breech upon firing to cycle the entire bolt assembly or slide. This mechanism, characterized by fixed barrels and minimal parts, ensures high reliability and compactness, making it popular for semiautomatic handguns like the UZI and AR-15 variants.

Delayed Blowback

Other Methods

Additional methods to delay blowback include using levers or gas pressure, exemplified by the Galil rifle and Beretta Model 92, respectively.

Not in current use in U. S. Army weapons, the delayed action bolt lock was formerly employed in some automatic weapons to prevent excessive rapidity of fire. These arrangements provide no positive lock of the closure; they permit the bolt to be moved rearward by propellant pressure, but delay the movement by forcing the pressure to overcome a mechanical disadvantage other than inertia.

ARMY MATERIEL COMMAND ALEXANDRIA VA. (1964)

Delayed action bolts include:

(a) Crank-type. The bolt is linked by a connecting rod to a crank pivoted in the receiver, so that reciprocating movement of the bolt produces oscillation of the crank. At closed bolt position, ihe crank arm and connecting rod are nearly Aligned, so that rearward pressure on the bolt produces a very small rotational component of force at the crank pin and initial rearward movement of the bolt is impeded.

(b) Rolling-contact-type. This is a modification of the crank-type, in which the end of the crank arm and the crank end of the connecting rod are rounded abutting surfaces held in contact by an additional link. The effect of this modification is to retard the increase of the rotational component of force on the crank arm during the initial stage of rotation, and so to produce a greater delay than the simple crank device.

(c) Inclined-contact- or wedge-type. In closed position, the bolt and receiver (or barrel) are connected by mating interrupted threads, or by a transverse sliding bar, with the engaged surfaces inclined at such an angle that a positive lock is not obtained. When the propellant pressure acts on the bolt, rearward movement is impeded until the small component of force parallel to the inclined surfaces rotates or slides the opposing members out of engagement.

Recoil-Operated vs. Blowback Firearms

Recoil-operated firearms feature barrel travel, distinguished by short and long recoil actions. The former, typified by handguns like the Colt 1911, employs locking lugs or cams to lock the barrel. Long-recoil-operated arms, more common in long guns, retain the action and barrel locked during recoil. An alternative is the blow-forward action, where recoil forces propel the barrel forward.

References

ARMY MATERIEL COMMAND ALEXANDRIA VA. (1964). ENGINEERING DESIGN HANDBOOK. GUNS SERIES GUNS-GENERAL.

Walker, R. E. (2012). Cartridges and firearm identification. CRC Press.