When purchasing certain types of lenses, such as telescopic sights or binoculars, you may have come across intriguing terms like “coated,” “multi-coated,” or “fully coated.” What on earth do these mean, and why is it crucial to understand the difference between these terms? Let’s find out!

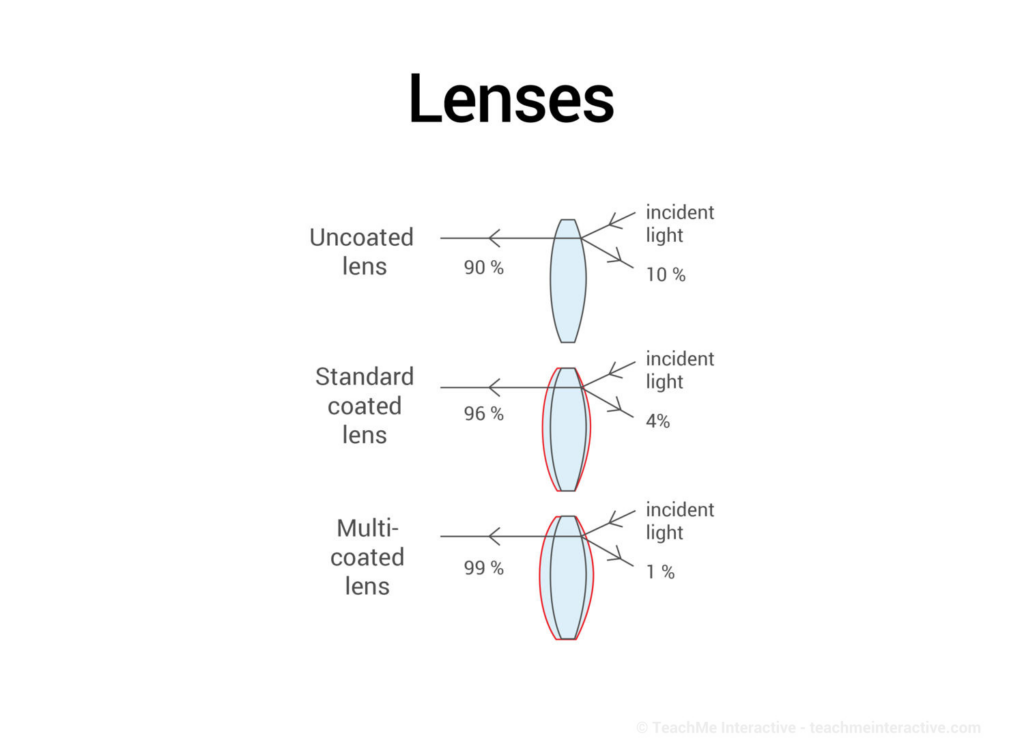

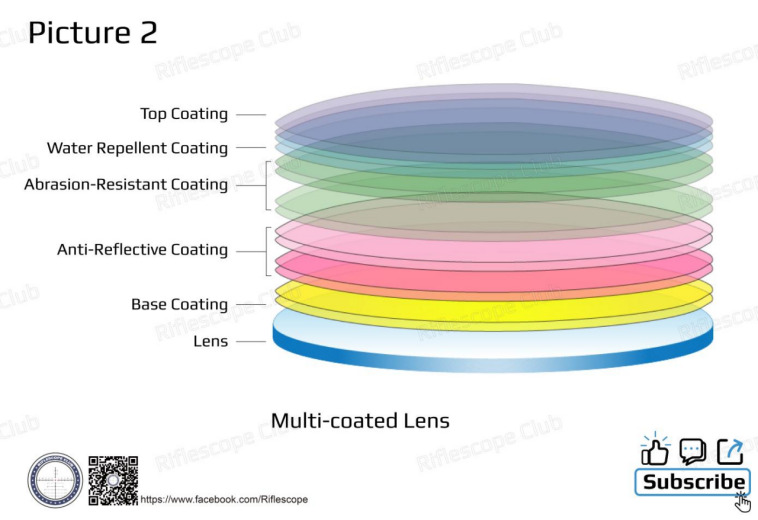

Optical coatings serve to diminish internal light loss and glare, ensuring uniform light transmission that culminates in enhanced image sharpness and contrast. The application of coatings on optics results in a subdued, often dark appearance when peering into the barrel or tube, with a potential tint of greenish, bluish, or brownish hues attributed to the magnesium fluoride or calcium fluoride composition.

Glass surfaces can undergo various coatings for multiple purposes. Take, for example, your car windows. It’s highly probable that they are coated to repel water, minimize glare, and decrease the transmission of light and heat into the car’s interior. Similarly, lenses with AR (anti-reflective) coatings are frequently found on optics like rifle scopes, laser rangefinders, binoculars, and spotting scopes. Irrespective of the optical device they are applied to, lens coatings serve identical purposes and are maintained using the same eyeglass cleaners.

“Anti-reflection coatings usually consist of a number of very thin transparent film layers, each having a distinct index of refraction to alter the lens performance with different wavelengths and at different angles of incidence. Sometimes, you can see these coatings by looking for blue, red, or green reflections as you look into the front of an optic’s objective lens at different angles.” (2)

These coatings employ a destructive interference mechanism, selectively eliminating certain colors or wavelengths of light and thereby reducing reflection. Consequently, a greater amount of light permeates the optics, facilitating its passage to the observer’s eyes.

“Lens coatings can also be specifically formulated to repel moisture. These coatings provide the benefits of reducing water spots and preventing rain and snow from sticking to the lens. However, more importantly, these coatings can eliminate fogging.

The fogging of lenses occurs when the temperature of the lens is lower than the dew temperature of the air. Fogging can be inevitable in warm, humid air because the dew point is close to the ambient air temperature. Under these conditions, the lenses may fog even if they are only a few degrees colder than the air temperature.

Fogging can also occur in cold conditions in which the lenses become quite cold, and moisture from your respiration or perspiration can condense on the cold lenses. Under these conditions, condensation can even freeze and form frost on the lenses.

Lens coatings repel moisture by providing a surface that is so slick that the moisture rolls off the lens rather than sticking. For example, our EXO Barrier™ technology bonds to the lens on a molecular level and fills in the pores in the lens so that beads of water have nothing to stick to.” (3)

In the realm of modern consumer optics, nearly all instruments incorporate some form of coating elements, albeit varying in levels and qualities. Celestron, as an example, offers distinct levels of coatings for optical tubes, binoculars, and spotting scopes, each denoting the extent of coverage on the optical surfaces. These levels include:

- Coated: At least one major optical element features a coating on one surface.

- Fully Coated: All lenses and glass surfaces are coated, encompassing the long side of the prism for binoculars.

- Multi-Coated: At least one major optical element in a fully-coated binocular has multiple coatings of anti-reflective compounds on one surface.

- Fully Broadband Multi-Coated: Primarily found in certain binoculars and spotting scopes, this coating reduces surface reflectivity, enhancing optical throughput across the entire visible light spectrum.

- Fully Multi-Coated: All glass surfaces boast multiple coatings, resulting in optimal light transmission (90-95%) for vivid, sharp, and high-contrast images.

In conclusion, understanding the intricacies of lens coatings is pivotal, especially in the realm of firearms and optics. Whether it’s the anti-reflective coatings on rifle scopes or the protective coatings on car windows, these applications play a crucial role in enhancing clarity, reducing glare, and ensuring optimal performance. Choosing the right coating for specific optical devices, such as scopes and binoculars, contributes significantly to their functionality. As with any precision equipment, proper care and maintenance, using suitable eyeglass cleaners, are essential to preserve the integrity and longevity of these coated lenses. So, the next time you look through your firearm optics, remember that the coatings are not just a technical detail – they are key to unlocking better visibility, accuracy, and overall performance in the field.

References:

- Celestron – https://www.celestron.com/blogs/knowledgebase/what-are-the-differences-between-the-optical-coatings

2. Hunting Optics – http://huntingoptics.net/anti-reflection-lens-coatings/

3. Bushnell – https://www.bushnell.com/through-the-lens/bu-blog-antireflective-coated-lenses-and-their-role-on-optics.html

4. Vector Optics – https://www.vectoroptics.com/about/view/id/72.html

5. Long Range Shooting – https://www.longrangeshooting.org/articles/scope-internal-anatomy