JHP? FMJ? BT? What the heck do these acronyms mean that designate the different bullet tips used by ammunition manufacturers?

Let’s start with a list. Take notes!

LRN – Lead Round Nose

Round nose lead bullets, known for their traditional design with a rounded tip, were once the prevailing choice in ammunition. Over time, their role has evolved, and they are now predominantly associated with training rounds due to their cost-effectiveness. These projectiles are characterized by their simple yet effective construction, which can offer some advantages depending on the application.

LFN – Lead Flat Nose

Some ammunitions, such as the .40 S&W, use flat-nosed bullets as a standard. The lead version of these bullets follows the same design, reducing production costs. The lead flat nose bullet type is exceptionally popular for those seeking excellent performance in shooting matches or general target practice. Its flat nose design offers the advantage of clear penetration visibility on paper targets, resulting in cleaner holes and reduced radial tearing, making scoring much more straightforward.

The advantages of lead flat nose bullets include their impressive hole visibility on targets. Although wadcutter bullets might excel in creating clean holes in paper, they often do not feed well in semi-automatic and lever-action firearms. Semi-flats serve as a viable compromise, and certain shooting competitions permit their use.

On the other hand, the primary drawback of this bullet type lies in its somewhat limited applications. While some variations are designed for home defense or specific firearms, lead flat nose bullets are predominantly associated with target shooting. Although some hunters may choose them for small game hunting, this isn’t a widespread practice. Additionally, due to the exposed lead, indoor ranges and certain areas may not allow their use.

LSWC – Lead Semi Wadcutter

Semi-wadcutter bullets are important for shooting paper targets. They leave well-defined marks on these targets, making them easier to evaluate.

LWC – Lead Wadcutter

Similar to LSWCammunition, LWC ammunition aims to mark paper targets as clearly as possible to facilitate evaluation.

SCHP – Solid Copper Hollow Point

Copper is less dense than lead, allowing a bullet of the same size to have less weight and, occasionally, more speed.

The Solid Copper Hollow Point bullet, or SCHP, finds applications in both rifle and pistol ammunition. While all-copper pistol bullets feature the typical large hollow point, rifle versions offer a broader selection. Different rifle ammunition types cater to varying game sizes, allowing the copper hollow point to adapt its expansion characteristics to specific targets. Whether for deer hunting or varmint control, the choice of SCHP ammunition varies accordingly.

This environmentally friendly, lead-free option is suitable for regions promoting “lead-free” practices, including ranges and hunting areas. Prominent manufacturers of SCHP bullets include well-known names such as Magtech and Barnes.

HPFN – Hollow Point Flat Nose

These are expanding bullets that maintain their flat tip, as the name suggests. Sometimes, this shape is required due to specific ammunition characteristics or results from different design adaptations.

FMJ – Full Metal Jacket

Ever heard of “Full Metal Jacket”? Well, there you have it. These are lead bullets with a metal jacket, aiming to combine the density and hardness of different metals.

The term “full metal jacket” refers to lead bullets encased in a harder metal, often copper or other materials like hybrid composites. Manufacturers of full metal jacket (FMJ) ammunition offer a wide range of options in their product lines, allowing you to choose from various materials, styles, and applications.

Full metal jacket ammo may also go by different names, such as “full metal case,” and it might include suffixes like “boat tail” to indicate the bullet’s intended purpose or performance characteristics. Common variations include full metal jacket boat tail, full metal jacket flat nose, and full metal jacket truncated cone, each tailored for specific uses while retaining the fundamental characteristics of FMJ rounds.

TMJ – Total Metal Jacket

A total metal jacket bullet, often abbreviated as TMJ ammo, is entirely enclosed by a jacket. These rounds are commonly utilized by shooters during range training, offering ballistic characteristics similar to full metal jacket or “ball” ammunition. A total metal jacket bullet may also be denoted as an FMJ-FEB, with “FEB” signifying “fully enclosed base.” This distinction sets it apart from standard FMJ ammunition, where the jacket encompasses the entire projectile except for the base. TMJ bullets feature a copper jacket that completely encloses the entire bullet, including the lead base.

FMJFN – Full Metal Jacket Flat Nose

Some ammunition requires the flattened shape of the projectile to achieve the desired weight along with thickness. This is nothing more than an FMJ ammunition with a slightly different geometry, typically found in .40 S&W or in the heavier 9x19mm projectiles.

JHP – Jacketed Hollow Point

The jacketed hollow point (JHP) is engineered for rapid expansion upon impact, enhancing bullet effectiveness and reducing the risk of over-penetration. Jacketed hollow points offer a wide array of options, distinguished by their shape, design, or manufacturer. When comparing JHP vs. HP, some jacketed hollow points closely resemble traditional hollow points but feature an evident coating.

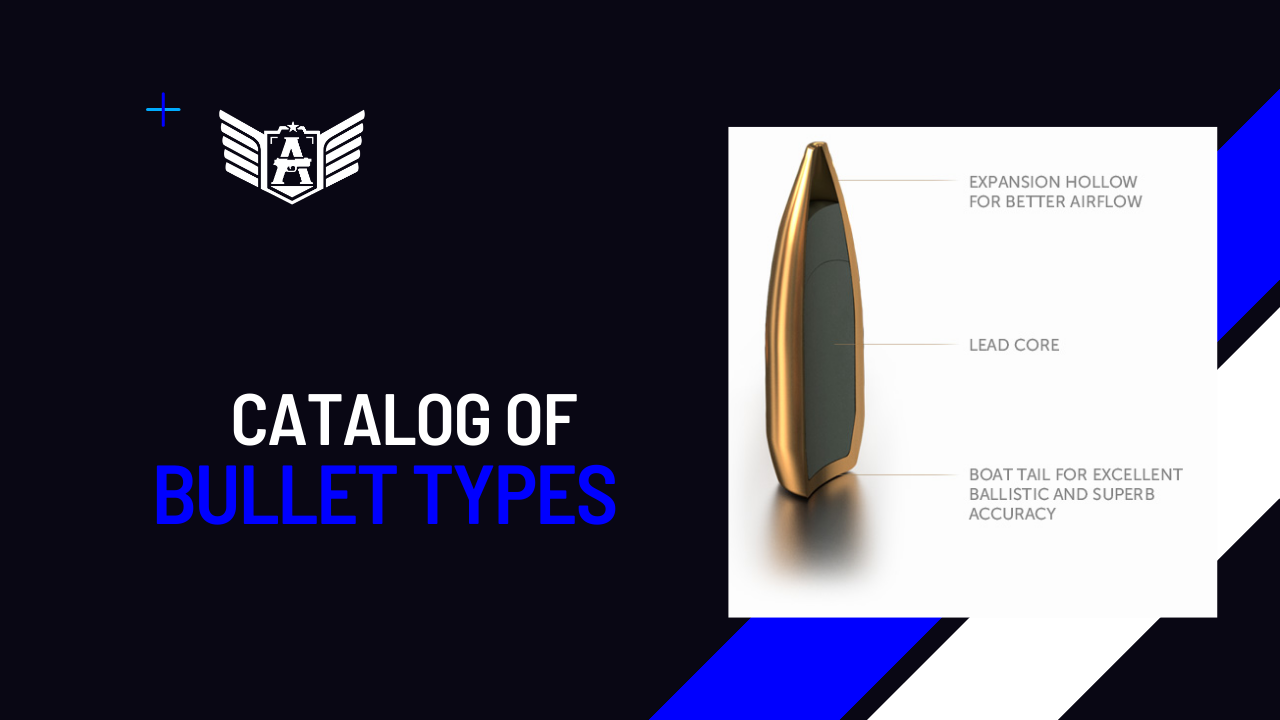

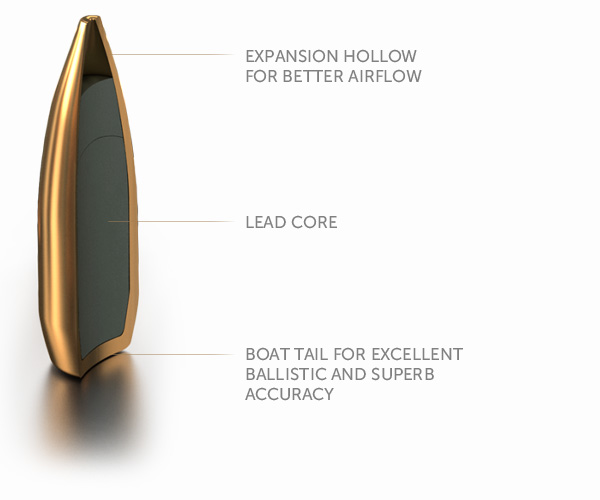

FMJBT – Full Metal Jacketed Boat Tail

“Boat Tail” refers to the shape of the bullet’s base, which doesn’t stop abruptly but rather tapers gradually, improving aerodynamics. Traditional rifle bullets feature a flat base design with a perpendicular base, while boat tail bullets are tapered toward the base, resembling the narrowing stern of a boat. This boat tail design reduces drag and improves ballistic performance.

The boat tail bullet design provides practical benefits in hunting and shooting scenarios, including improved wind resistance, increased downrange velocity and energy retention, and flatter trajectories. Boat tail bullets are less sensitive to crosswinds, making them valuable for long-range shooting in outdoor conditions. They also maintain speed and energy better over long distances, ensuring effective performance and mushrooming when needed. Additionally, boat tail bullets experience less drop, resulting in flatter trajectories, which enhance accuracy for both hunters and target shooters.

HPBT – Hollow Point Boat Tail

The hollow point boat tail bullet (HP-BT), also referred to as boat tail hollow point or BTHP ammo, is primarily utilized in rifles for long-range hunting of large game and sometimes for coyote and wolf hunting. Similar to other hollow points, this bullet rapidly expands upon impact, creating an extensive wound channel, often incapacitating most animals with a single shot.

The boat tail design enhances accuracy and is favored by many hand reloaders due to its tapered tail, which easily integrates with casings without accidental scratches or dents.

When exploring hollow point boat tail ammunition, you’ll encounter a variety of options from different manufacturers, each offering unique tips, casings, and production methods. One notably popular choice for competitive shooting is the Match King bullet from Sierra.

Polymer Tip

A bullet’s ballistic coefficient measures its ability to overcome air resistance and retain velocity during flight, resulting in a flatter trajectory and increased energy upon impact. Manufacturers often use polymer tips to standardize meplat shapes, enhancing the bullets’ ballistic coefficients and performance. While polymer tips aim to improve uniformity and streamline meplats, some experienced shooters may not perceive significant accuracy improvements compared to traditional bullets, particularly in the context of match shooting ammunition.

Polymer tips serve various purposes in bullets. In hunting bullets like Hornady’s V-MAX, the tip ensures rapid, uniform expansion upon impact. It crushes into the nose cavity, pushing the bullet to expand further as it penetrates the target. Winchester’s Extreme Point features a wide-based polymer tip for faster expansion. Self-defense bullets like Hornady’s FTX also employ polymer tips to achieve reliable expansion, as the tip compresses upon contact with soft tissue, aiding bullet expansion. Moreover, polymer tips prevent nose cavities from clogging with debris when penetrating barriers or targets, preserving a bullet’s ability to achieve effective terminal expansion, as seen in Speer’s G2 bullet containing elastomer to maintain cavity clearance.

Frangible

Frangible bullets are designed to break into tiny fragments upon impact with a target, reducing their ability to penetrate other objects. These small fragments are rapidly slowed down by air resistance, minimizing the risk of causing harm or damage to people and objects at a distance from the impact point.

Most frangible bullets are prone to brittle failure when they hit a hard target. This feature helps prevent malleable lead and copper bullets from ricocheting off hard surfaces as large, solid pieces. Brittle failure can occur even at subsonic velocities. Attempts to crimp a brittle frangible bullet into a cartridge case may result in the bullet breaking. In semi-automatic firearms, brittle frangible bullets may break during the self-loading cycle, and in revolvers, they can fracture as they encounter the barrel’s forcing cone after leaving the cylinder.

Manufacturing methods for frangible bullets may involve variations in weight and length compared to conventional bullets of the same caliber. These bullets are typically produced using powder metallurgy techniques, where mixtures of powdered metals (such as tin, copper, zinc, and/or tungsten) are compressed at room temperature to create a high-density material. Mechanical interlocking and cold welding bond the metals together, either by pressing them directly into shape or by forming bar stock billets that can be swaged into projectiles, with or without jacketing.

Alternative manufacturing techniques include heat treatment or sintering of powdered metals at temperatures below their melting points, as well as binding powdered metal with adhesives or polymers through injection molding processes.

M193

M193 represents the typical 5.56x45mm projectile, weighing 55gr.

In 1970, NATO members signed an agreement to select a second, smaller caliber cartridge to replace the 7.62×51mm NATO cartridge.[12] Of the cartridges tendered, the .223 Remington (M193) was the basis for a new design created by FN Herstal. The FN-created cartridge was named “5.56×45mm NATO” with a military designation of SS109 in NATO and M855 in the U.S.[13] These new SS109 ball cartridges required a 228 mm (1-in-9 inch) twist rate while adequately stabilizing the longer L110 tracer projectile required an even faster, 178 mm (1-in-7 inch), twist rate.[5]

The Belgian 62 gr SS109 round was chosen for standardization as the second NATO standard rifle cartridge which led to the October 1980 STANAG 4172. The SS109 used a 62 gr full metal jacket bullet with a seven grain mild steel tip to move the center of gravity rearward, increasing flight stability and thereby the chances of striking the target tip-first at longer ranges, in part to meet a requirement that the bullet be able to penetrate through one side of a WWII U.S. M1 helmet at 800 meters (which was also the requirement for the 7.62×51mm NATO). An actual helmet was not used for developmental testing, but an SAE 1010 or SAE 1020 mild steel plate, positioned to be struck at exactly 90 degrees. It had a slightly lower muzzle velocity but better long-range performance due to higher sectional density and a superior drag coefficient. This requirement made the SS109 (M855) round less capable of fragmentation than the M193.

Wikipedia

SS109

The SS109 is a 5.56 projectile with 62gr, suitable for barrels with a rifling twist rate of 1:7.

L110

L110 Ammunition These are 5.56 projectiles with 62gr weight, featuring tracers.

M855 – SAT – Steel Arrow Tip

M855projectiles have steel tips, weigh 62gr, and are developed for the 5.56x45mm caliber.

IR-Tracer

7.62x51mm IR Tracer Ammunition IR Tracer projectiles are manufactured by CBC in 5.56x45mm and 7.62x51mm calibers. They are distinctive for producing a visible trace exclusively for operators equipped with infrared night vision equipment.

Other nomenclatures and Final Considerations

You can find also a lot of other terms not listed here. Let’s see some examples:

- MC (Metal Cased): This is a term used by Remington to refer to their full metal jacketed bullets.

- BJHP = Brass Jacketed Hollow Point

- WFN = Wide Flat Nose

- WFNGC = Wide Flat Nose Gas Checked

- LSWCHP = Lead Semi Wad Cutter Hollow Point

- STHP = Silver Tip Hollow Point

- TFSP = Total Fragmenting Soft Point

- SJSP = Semi Jacketed Soft Point

- SJHP = Semi Jacketed Hollow Point

- LHP = Lead Hollow Point

- CLL = Cowboy Lead Load

- JSP = Jacketed Soft Point

- FNEB = Flat Nose Enclosed Base

- PTHP = Platnium Tip Hollow Point

- HSP = Hollow Soft Point

So, did I help or confuse? It’s not easy, of course, to memorize all these acronyms and designations. But keep this guide in your favorites, come back to it when you need it, and if you have any suggestions or questions, write them in the comments.