by Paulo Wypych

It is very important that for a quality reload, we take into consideration various factors that, when applied together, will inevitably result in your ammunition being accurate and perfect.

With this objective in mind, I will list the ten most common errors that we may eventually make during the ammunition reloading process, and therefore, we must avoid them.

- Not using safety equipment. It is known that when reloading, we handle elements like lead and gunpowder, which contain other potentially harmful elements to our health. In addition to possible mechanical problems such as the untimely detonation of a primer, which could project something into our eyes. Therefore, safety measures and equipment such as protective goggles, a well-ventilated environment, and not handling food during reloading are essential.

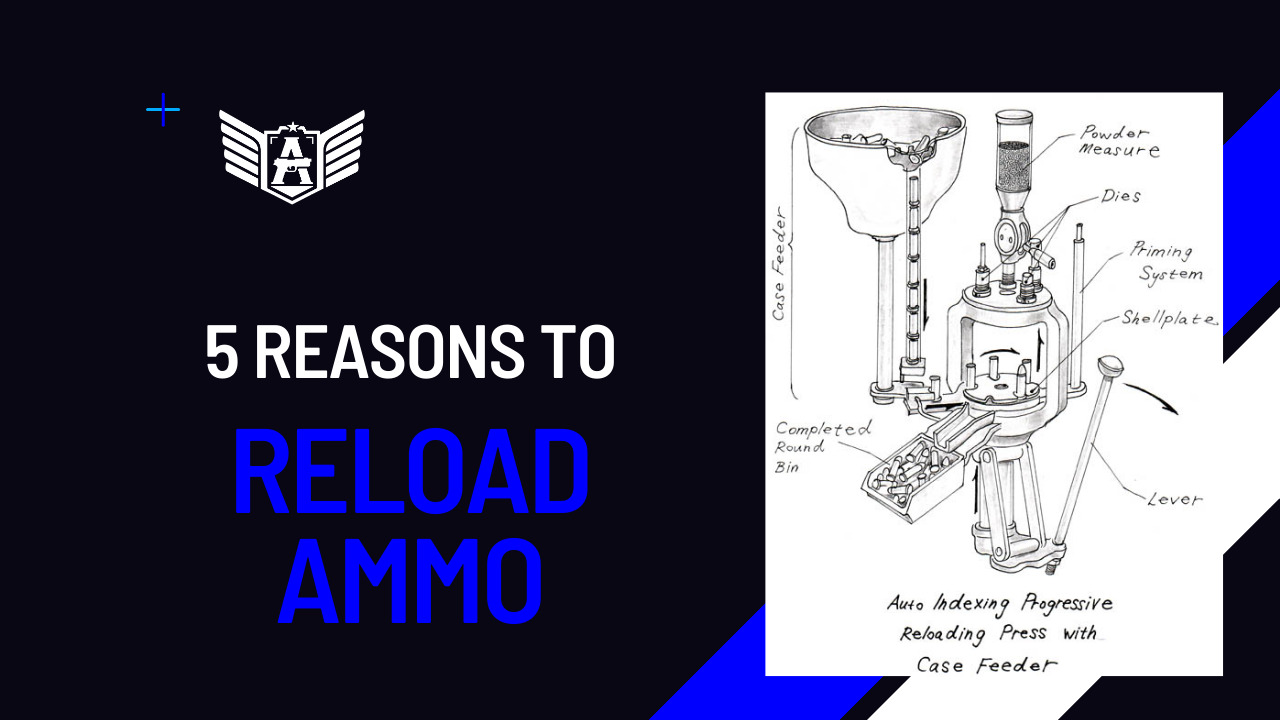

- Not having quality equipment. It may seem extravagant, but in reality, when we are in such an important field that prioritizes quality and safety, it is not! Having good equipment – I won’t go into details about brands or specifics – is crucial to achieve the desired quality and safety in the reloads.

- Not properly storing your components. Gunpowder and primers can absorb moisture and, as a result, fail or significantly lose their energy. Consequently, this can lead to frustration, malfunctions, accidents, or incidents. Therefore, keeping the components well stored is of paramount importance.

- Not installing the press on a solid base. I understand that some people are eager to have a reloading press at home and can’t wait to start reloading. Consequently, they end up installing their presses on fragile or inappropriate bases. This will certainly result in low-quality ammunition.

- Not choosing the appropriate components correctly. Often, people copy recipes that others have used and do not seek technical information about the specific reload required. Choosing the correct gunpowder, in the right quantity, and the ideal projectile weight will certainly lead to a longer life and safety for your equipment, not to mention the quality and performance of your shots.

- Correct adjustment of the DIES. It may seem obvious to talk about this, but it’s not. There are various techniques, types of DIES, and ways to reload ammunition. There is no single absolute truth, but rather several good methods, depending on the type of reload and ammunition being used. Therefore, study, seek information, and take courses on the subject to avoid mistakes and unnecessary wear.

- The gold press. Well, I know this topic can be subjective, but my scope is to help as much as I can. There is no need to buy the most expensive press in the world to reload. The value of the press is not directly proportional to the quality of the ammunition, but knowledge is! So buy what is best for your reality. Calculate your future production goals and invest in a good reloading machine; there are many on the market, including domestic options, and be happy.

- Not performing periodic maintenance. Machines should also be treated with care. If given proper care and preventative maintenance, they will never let you down.

- Not testing your ammunition. Right after making your reloads, set aside a small batch, go to a shooting range, and “run” your ammunition through a chronograph to check the energy of each one. Check if they are varying, if they are within the desired standard, and so on.

- Not checking the adjustments. Whenever you change batches of components (gunpowder and primers), re-adjust your equipment. And even if you don’t change the batches, be careful to check the parameters periodically.

These are the ten topics that I believe are the most important and common to happen in the daily routine of ammunition reloaders.

Do you make any of these mistakes? Is there another one you would like to add? Send your comments!